For more than 60 years, Gamma Scientific has produced the world’s most accurate equipment for precise light measurement.

The systems developed in our ISO/IEC 17025 accredited laboratory (NVLAP code 200823-0) are trusted by leading researchers, companies and government agencies to provide rapid, reliable light testing in diverse and challenging environments.

Whether your project is in early prototyping or volume production, we have the tools to ensure your products meet the highest quality standards. Contact us today to learn how we can provide a custom solution for you business.

Photonic Measurement, Calibration & Testing

Our Clients tackle the most complex and challenging problems their industries have. We give them the tools to succeed.

What Sets Us Apart

People

Together, Gamma Scientific staff represents centuries worth of work experience, advanced degrees, and pure research in light generation and measurement science.

Global Leadership/Support

Backed by an international network of manufacturing and distribution partners, we lead the world in providing, and supporting, photonic solutions

Award-Winning Innovation

Prism Finalist, Silver Honoree (LaserFocusWorld), Gold Honoree (LaserFocusWorld), Sapphire Award (LEDs Magazine).

Patented Tech

Our proprietary technology allows us to provide unique and creative solutions to your most complex issues. US Patent Nos. 10,257,509 and 10,972,721, European Patent No. 3497423.

Leadership

Spectroradiometers, Heads Up Display (HUD), Near-Eye-Display (NED™) measurement and testing systems. Gamma helped introduce these technologies and continues to improve upon their design and implementation.

Custom Solutions

We offer both fully automated and SDK-driven software solutions for our equipment.

Gamma Scientific Lights The Way

2026 SPIE Prism Award Finalist

Gamma Scientific’s 191 AR Coating Measurement System Named 2026 SPIE Prism Award Finalist San Diego, Jan. 16, 2026 – Gamma Scientific, a global leader in optical metrology, is proud to

Gamma Scientific Launches the NED™ E-Series GazeCam™

Compact Imaging Camera Engineered for Human Factors Testing of AR/VR/MR June 5, 2025 – San Diego, CA – Gamma Scientific announces the launch of the NED™ E-Series GazeCam™, the imaging

Gamma Scientific Launches SpectralLED® RS-9 Series

Uniform Tunable Light Source with Expanded Spectral Range in a Compact Design May 8, 2025 – San Diego, CA – Gamma Scientific, a global leader in optical metrology, announces the

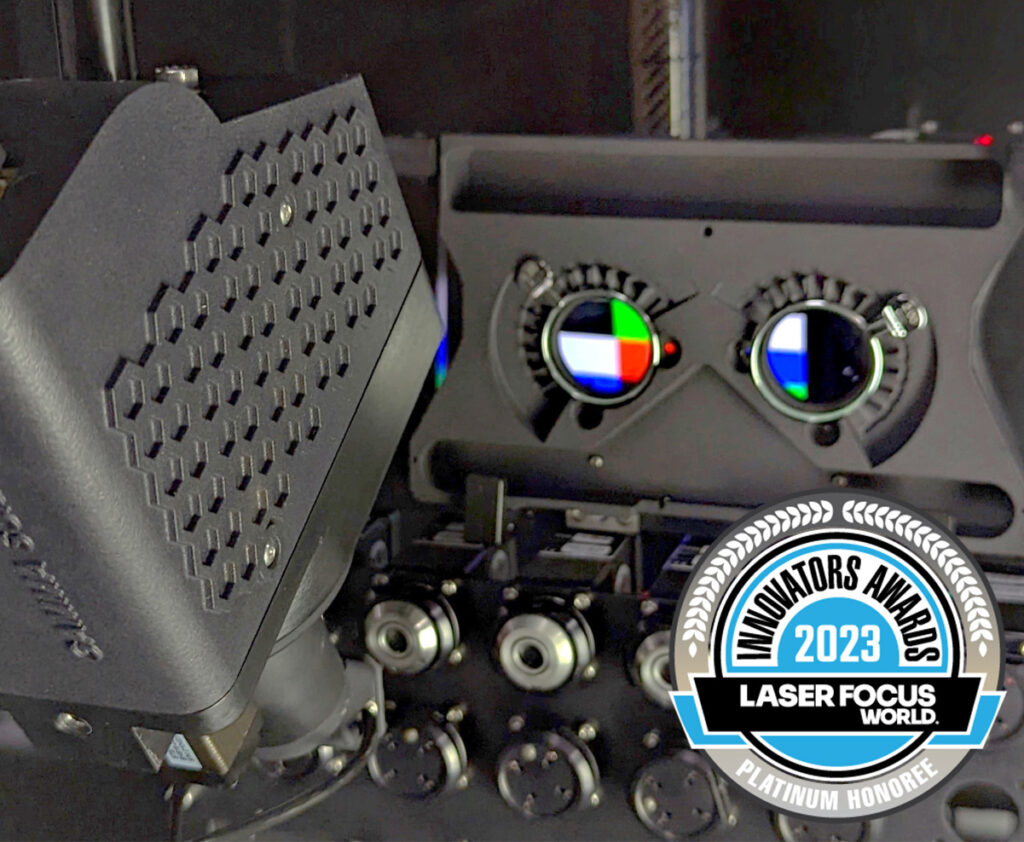

Gamma Scientific Honored by 2023 Laser Focus World Innovator Awards

The NED™ Rx-Series (Prescription) system was chosen to be a 2023 platinum honoree by 2023 Laser Focus World Innovators Awards. It’s the world’s first augmented reality (AR) and virtual reality (VR) test system allowing device makers to fully test their headsets across a broad range of human vision corrections to create a seamless and immersive experience for people who require vision-corrected glasses.